Abstract

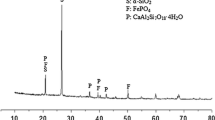

Composition, morphology, and structure of hydration products in hardened pastes of three kinds of blended cement (cement-silica fume, cement-quartz powder and cement-silica fume-quartz powder) hydrated under different curing regimes (standard curing, 90 °C steam curing, 200 °C and 250 °C autoclave curing) were investigated by X-ray diffraction and field emission scanning electron microscope equipped with EDAX system. Results showed that the main hydration products in three kinds of hardened pastes under standard curing condition are all C-S-H gels, CH, and AFt. Under 90 °C steam curing condition, the main hydration products of cement-silica fume and cement-silica fume-quartz powder are C-S-H gels, whereas those of cement- quartz powder are C-S-H and CH. Under 200 or 250 °C autoclave curing condition, no obvious crystallized CH phase is found in hardened pastes of three kinds of blended cement, and C-S-H gels are transformed into one or more crystalline phases such as tobermorite, jennite, and xonotlite. The chemical composition and morphology of these crystalline phases depend on the composition of mixture and autoclave temperature.

Similar content being viewed by others

References

QIN WZ, CAO F. A New Ultra-high Performance Concrete, Reactive Powder Concrete[J]. Industrial Construction, 1998, 29(4): 69–76

BONNEAU O, POULIN C, DUGAT J, et al. Reactive Powder Concrete: from Theory to Practice[J]. Concrete International, 1996, 18(4): 47–49

LIU JH, SONG SM. Reactive Powder Concrete-Preparation, Performance and Microstructure[M]. Beijing: Chemical Industry Press, 2013 (in Chinese)

AN MZ, YU ZR, SUN ML, et al. Fatigue Properties of RPC under Cyclic Loads of Single-stage and Multi-level Amplitude[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2010, 25(1): 167–173

PIERRE Y B, MARCO C P. Prestressed Pedestrian Bridge-world’s First Reactive Powder Concrete Structure[J]. PCI Journal, 1999(9–10): 60–71

BEHLOIL B, LEE K C, DUCTAL R. Seonyu Footbridge[J]. Structure Concrete, 2003, 4(4): 95–201

BIERWAGEN D, HAWASH A A. Ultra High Performance Concrete Highway Bridge[C]. Proceeding of the 2005 Mid-Continebt Transportation Symposium, Iowa, 2005

LIU SH, YAN PY, FENG JW. A Study and Application of Reactive Powder Concrete in Bridge Engineering[J]. Highway, 2009, 54(3): 149–154

SHUA JJ. Fatigue Reliability Design Principle Research of Prestressed-RPC High-speed Railroad Bridge[D]. Beijing: Beijing Jiaotong University, 2010

Gökçe HS, Sürmelioglu S, Andiç-Çakir Ö. A New Approach for Production of Reactive Powder Concrete: Lightweight Reactive Powder Concrete (LRPC)[J]. Materials and Structures, 2017, 50(1): 50–58

JIAO CJ, SUN W. Impact Resistance of Reactive Powder Concrete [J]. Journal of Wuhan University of Technology-Materials Science Edition, 2015, 30(4): 752–757

MARCEL C, VINCENT M, LAURENT F. Microstructural Analysis of RPC[J]. Cement and Concrete Research, 1995, 25(7): 1491–1500

HÉLÈNE Z, MARCEL C. Investigation of Hydration and Pozzolanic Reaction in Reactive Powder Concrete using 29Si NMR[J]. Cement and Concrete Research, 1996, 26(1): 93–100

Zhang QQ, WEI Y, Zhang J, et al. Influence of Steel Fiber Content on Fracture Properties of RPC[J]. Journal of Building Materials, 2014, 17(1): 24–29 (in Chinese)

LONG GC, XIE YJ, Wang PM, et al. Properties and Micro/Mecrostructure of Reactive Powder Concrete[J]. Journal of the Chinese Ceramic Society, 2005, 33(4): 456–461 (in Chinese)

WANG H, HAN S, An MZ, et al. Development of Microcosmic Study on Reactive Powder Concrete Materials[J]. Material Review, 2014, 28(7): 95–103 (in Chinese)

SHI QX, RONG C, ZHANG T. Development of Micro-level Study on Reactive Powder Concrete Materials[J]. Journal of Xi’an University of Architecture & Technology(Natural Science Edition), 2015, 47(2): 155–159 (in Chinese)

WANG YM, SU MZ. Sulphoaluminate Cement[M]. Beijing: Beijing University of Technology Press, 1999 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China(Nos.51272193, 51372183, 51072150), Program for New Century Excellent Talents in University (No.NCET-10-0660) and the National Key Research Projects (No.2016YFB0303501)

Rights and permissions

About this article

Cite this article

He, Y., Mao, R., Lü, L. et al. Hydration products of cement-silica fume-quartz powder mixture under different curing regimes. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 598–602 (2017). https://doi.org/10.1007/s11595-017-1640-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1640-8