Abstract

Digital light processing (DLP) 3D printing technology is widely applied in the fabrication of ceramics owing to the good printing precision and printing speed. Barium titanate (BaTiO3, BT) has attracted extensive attention of researchers due to the good piezoelectric constant, strong dielectric constant, and ease of integration. Therefore, DLP 3D printing technology is combined with the production of BaTiO3/1,6-ethylene glycol diacrylate/Polyethylene glycol (400) diacrylate (BT/HDDA/PEG(400)DA) nanocomposites to improve the electrical properties. A preparation method for composite slurry with high fluidity, high solid content, and low viscosity is proposed by comparing the electrical properties of BT/HDDA/PEG(400)DA nanocomposite fabrication with different solid content. The work demonstrates that 67 wt% BT/HDDA/PEG(400)DA nanocomposites are better solid content to DLP 3D printing technology and the printed nanocomposite has the excellent electric properties. After a post-processing, the 67 wt% nanocomposite slurry shows the higher relative density (91.69%) and exhibits piezoelectric constant, remnant polarization, and dielectric constant of 151 pC/N, 17.4 μC/cm2, and 7712, respectively. The results suggest that the DLP 3D printing technology provides an alternative method for the fabrication of complex functionality nanocomposite piezoelectric elements.

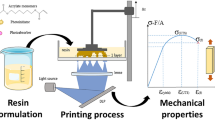

Graphical Abstract

Similar content being viewed by others

References

Ye D, Ding YJ, Duan YQ et al (2018) Large-scale direct-writing of aligned nanofibers for flexible electronics. Small 14:1703521–1703529

Ziaee M, Crane NB (2019) Binder jetting: a review of process, materials, and methods. Addit Manufact 28:781–801

Gaytan SM, Cadena MA, Karim H et al (2015) Fabrication of barium titanate by binder jetting additive manufacturing technology. Ceram Int 41:6610–6619

Grida I, Evans JRG (2003) Extrusion free forming of ceramics through fine nozzles. J Eur Ceram Soc 23:629–635

Kim H, Marquez AR, Islam MD et al (2019) Fabrication of bulk piezoelectric and dielectric BaTiO3 ceramics using paste extrusion 3D printing technique. J Am Ceram Soc 102:3685–3694

Chen W, Wang F, Yan K et al (2019) Micro-stereolithography of KNN-based lead-free piezoceramics. Ceram Int 45:4880–4885

Sotov A, Kantyukov A, Popovich A et al (2021) LCD-SLA 3D printing of BaTiO3 piezoelectric ceramics. Ceram Int 47:30358–30366

Han D, Yang C, Fang NX et al (2019) Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Addit Manufact 27:606–615

Tiller B, Reid A, Zhu B et al (2019) Piezoelectric microphone via a digital light processing 3D printing process. Mater Des 165:107593–107601

Li F, Ji X, Wu Z et al (2020) Digital light processing 3D printing of ceramic shell for precision casting. Mater Lett 276:128037–128044

Patel DK, Sakhaei AH, Layani M et al (2017) Highly stretchable and UV curable elastomers for digital light processing based 3D printing. Adv Mater 29:1606000–1606007

Colella R, Chietera FP, Catarinucco L (2020) Digital light processing as one of the promising 3D-printing technologies in electromagnetics: application on RFID. 2020 5th International Conference on Smart and Sustainable Technologies (SpliTech). IEEE. 1–4

Ligon SC, Liska R, Stampfl J et al (2017) Polymers for 3D printing and customized additive manufacturing. Chem Rev 117:10212–10290

Chen C, Wang X, Wang Y et al (2020) Additive manufacturing of piezoelectric materials. Adv Funct Mater 30:2005141–2005176

Griffith ML, Halloran JW (1997) Scattering of ultraviolet radiation in turbid suspensions. J Appl Phys 81:2538–2546

Qian CC, Hu KH, Lu ZG et al (2021) Volume shrinkage and conversion rate of Al2O3 ceramic stereolithography suspension polymerised by ultraviolet light. Mater Chem Phys 267:124661–124668

Hu W, Huang J, Zhang X et al (2020) A mechanically robust and reversibly wettable benzoxazine/epoxy/mesoporous TiO2 coating for oil/water separation. Appl Surf Sci 507:145168

Wang Z, Zhu H, Cao N et al (2017) Superhydrophobic surfaces with excellent abrasion resistance based on benzoxazine/mesoporous SiO2. Mater Lett 186:274–278

Li X, Zhao S, Hu W et al (2019) Robust superhydrophobic surface with excellent adhesive properties based on benzoxazine/epoxy/mesoporous SiO2. Appl Surf Sci 481:374–378

Arun A, Malrautu P, Laha A et al (2021) Gelatin nanofibers in drug delivery systems and tissue engineering. Eng Sci 16:71–81

Gao S, Zhao X, Fu Q et al (2022) Highly transmitted silver nanowires-SWCNTs conductive flexible film by nested density structure and aluminum-doped zinc oxide capping layer for flexible amorphous silicon solar cells. J Mater Sci Technol 126:152–160

Pan D, Yang G, Abo-Dief HM et al (2022) Vertically aligned silicon carbide nanowires/boron nitride cellulose aerogel networks enhanced thermal conductivity and electromagnetic absorbing of epoxy composites. Nano-micro Lett 14(1):1–19

Li F, Cabral MJ, Xu B et al (2019) Giant piezoelectricity of Sm-doped Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals. Science 364:264–268

Bian L, Qi X, Li K et al (2020) High-Performance [001] c-Textured PNN-PZT Relaxor ferroelectric ceramics for electromechanical coupling devices. Adv Funct Mater 30:2001846–2001853

Zou D, Liu S, Zhang C, Hong Y et al (2021) Flexible and translucent PZT films enhanced by the compositionally graded heterostructure for human body monitoring. Nano Energy 85:105984–105992

Gao B, Yao Z, Lai D, Guo Q, Pan W, Hao H, Liu H (2020) Unexpectedly high piezoelectric response in Sm-doped PZT ceramics beyond the morphotropic phase boundary region. J Alloys Compd 836:155474–155480

Wada S, Takeda K, Muraishi T et al (2007) Preparation of [110] grain oriented BaTiO3 ceramiacs by templated grain growth method and their piezoelectric properties. Jpn J Appl Phys 46:7039–7043

Lou Q, Shi X, Ruan X et al (2018) Ferroelectric properties of Li-doped BaTiO3 ceramics. J Am Ceram Soc 101:3597–3604

Ma JP, Chen XM, Ouyang WQ et al (2018) Microstructure, dielectric, and energy storage properties of BaTiO3 ceramics prepared via cold sintering. Ceram Int 44:4436–4441

Wang N, Jain A, Li Y et al (2020) Investigation of structural, ferroelectric and magnetic properties of Ca modified BiFeO3–BaTiO3 ceramics. Ceram Int 46:3855–3860

Goat CA, Whatmore RW (1999) The effect of grinding conditions on lead zirconate titanate machinability. J Eur Ceram Soc 19:1311–1313

Chen X, Sun J, Guo B et al (2022) Effect of the particle size on the performance of BaTiO3 piezoelectric ceramics produced by additive manufacturing. Ceram Int 48:1285–1292

Shintaku H, Nakagawa T, Kitagawa D, Tanujaya H, Kawano S, Ito J (2010) Development of piezoelectric acoustic sensor with frequency selectivity for artificial cochlea. Sensors Actuat A Phys 158:183–192

Liu K, Zhou C, Hu J et al (2021) Fabrication of barium titanate ceramics via digital light processing 3D printing by using high refractive index monomer. J Eur Ceram Soc 41(12):5909–5917

Rosental T, Mizrahi S, Kamyshny A et al (2021) Particle-free compositions for printing dense 3D ceramic structures by digital light processing. Virtual Phys Prototyp 16(3):255–266

Liu K, Hu J, Du Y et al (2022) Influence of particle size on 3D‐printed piezoelectric ceramics via digital light processing with furnace sintering. Int J Appl Ceram Technol

Gong P, Li Y, Xin C et al (2022) Multimaterial 3D-printing barium titanate/carbonyl iron composites with bilayer-gradient honeycomb structure for adjustable broadband microwave absorption. Ceram Int 48(7):9873–9881

Wang H, Li Y, Wang X et al (2021) Preparation and characterization of piezoelectric foams based on cyclic olefin copolymer. Eng Sci 16:203–210

Su YF, Han G, Kong Z et al (2020) Embeddable piezoelectric sensors for strength gain monitoring of cementitious materials: the influence of coating materials. Eng Sci 11(10):66–75

Wang W, Sun J, Guo B et al (2020) Fabrication of piezoelectric nano-ceramics via stereolithography of low viscous and non-aqueous suspensions. J Eur Ceram Soc 40:682–688

Vijatović MM, Bobić JD, Stojanović BD (2008) History and challenges of barium titanate: part II. Sci Sinter 40:235–244

Chen Z, Song X, Lei L et al (2016) 3D printing of piezoelectric element for energy focusing and ultrasonic sensing. Nano Energy 27:78–86

Kasai T, Ozaki Y, Noda H et al (1989) Laser-Sintered Barium Titanate. J Am Ceram Soc 72:1716–1718

Funding

This work was supported in part by the National Natural Science Foundation of China (No. 21005003), the Natural Science Basic Research Plan in Shaanxi Province of China (2019JM-091), the Scientific Research Foundation of Shaanxi Provincial Key Laboratory (No. 18JS008), the Scientific Research Program Funded by the Department of Science and Technology of Shaanxi Province (No. 2019JQ-897), the Doctoral Scientific Research Starting Foundation of Baoji University of Arts and Science (No. ZK2018059), and the Baoji University of Arts and Sciences Innovative Research Projects of Postgraduates (No. YJSCX20YB19).

Author information

Authors and Affiliations

Contributions

Cheng Chen and Xi Wang wrote the main manuscript text. Yan Wang prepared Figs. 1, 2, 3, and 4. Hongxi Gu and Weixing Zhao investigated the work and provided experimental ideas. Wenxiong Zhang and Galhenage Asha Sewvandi support the editing services. Bo Wang, Chunrui Ma, and Ming Liu edited and polished the work. Dengwei Hu provided the funding support. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

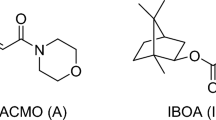

1. The BT/HDDA/PEG(400)DA nanocomposite slurry with excellent photoactive, high solid content, and low viscosity was developed for the digital light processing (DLP) 3D printing technology.

2. The DLP 3D printed BT/HDDA/PEG(400)DA nanocomposite were investigated infrequently and the nanocomposite were successfully fabricated with high precision and fast printing speed.

3. The relationship between the BaTiO3 content in the slurry and electrical properties of nanocomposites fabricated by DLP 3D printing technology was clarified. The results reveals that the dielectric, piezoelectric and ferroelectric properties of the fabricated BT/HDDA/PEG(400)DA nanocomposites is relatively high when the solid content of BaTiO3 powder is 67 wt%.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, C., Wang, X., Wang, Y. et al. Digital light processing 3D printing of barium titanate/1,6-ethylene glycol diacrylate/polyethylene glycol (400) diacrylate nanocomposites. Adv Compos Hybrid Mater 6, 41 (2023). https://doi.org/10.1007/s42114-022-00617-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-022-00617-w